The Top 10 Most Innovative Additive Manufacturing Companies

Oct 3, 2024

The Top 10 Most Innovative Additive Manufacturing Companies

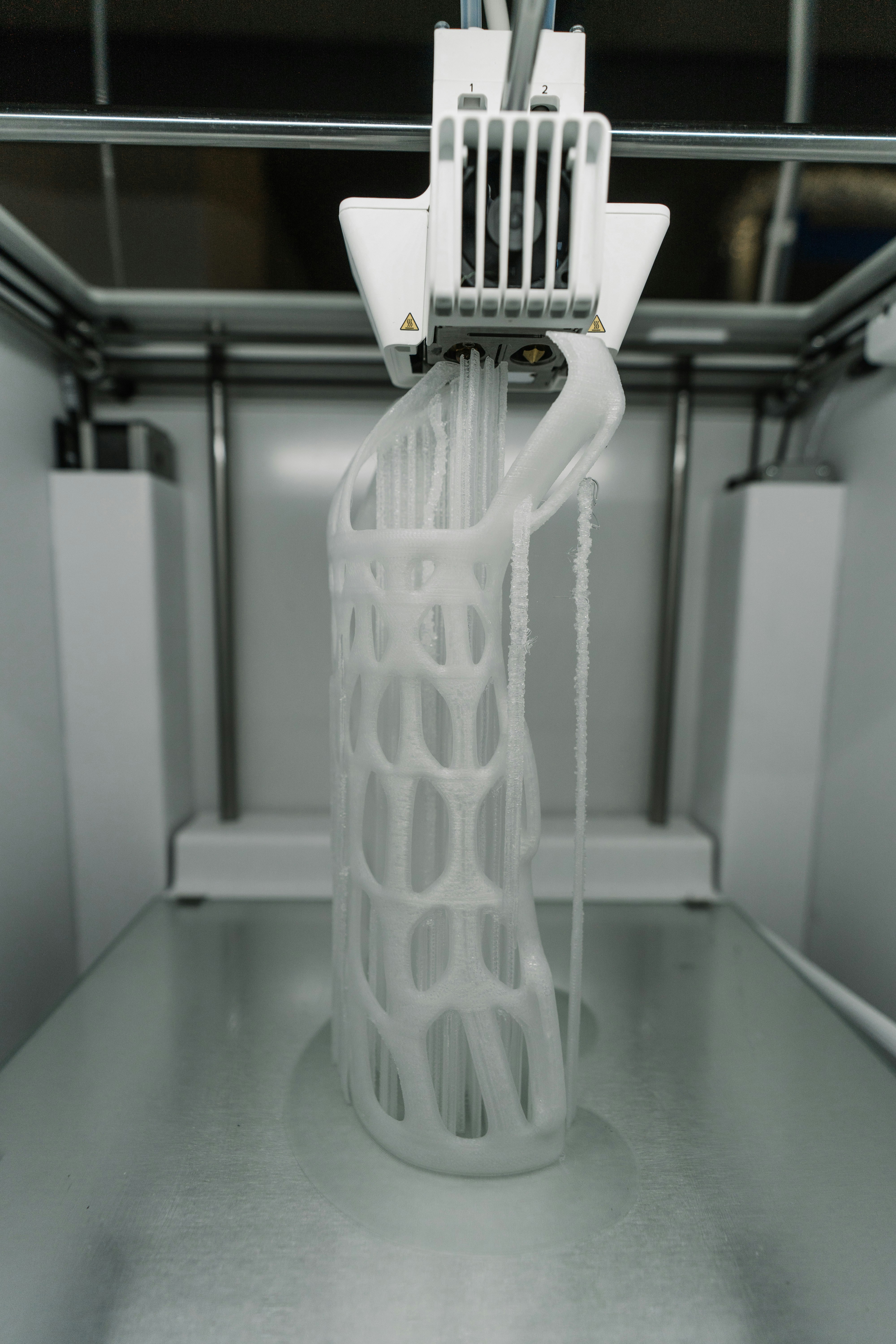

Additive manufacturing, commonly known as 3D printing, has revolutionized industries by transforming the way we approach design, prototyping, and production. From aerospace to healthcare, the ability to create complex structures with unprecedented precision is unlocking new possibilities every day. In this blog, we spotlight the top 10 most innovative additive manufacturing companies that are pushing the boundaries of what’s possible.

What Makes a Good 3D Printing Company

A good 3D printing company is characterized by its commitment to innovation, quality, and customer satisfaction. Key attributes include:

• Technological Innovation: Continual development of new technologies or enhancement of existing ones to improve printing speed, accuracy, and capabilities.

• Material Diversity: Offering a wide range of materials—from plastics to metals and composites—to cater to various industry needs.

• User-Friendly Solutions: Providing hardware and software that are accessible and easy to use, lowering the barrier to entry for users of all skill levels.

• Exceptional Customer Support: Maintaining a dedicated support system to assist users, fostering trust and long-term relationships.

• Scalability and Flexibility: Delivering solutions that can adapt to the demands of both small businesses and large-scale industrial operations.

• Community Engagement: Building a community around their products for shared learning, innovation, and collaboration.

These qualities not only define a company’s current success but also position it to lead future advancements in the rapidly evolving field of additive manufacturing.

Who This Blog Is For

This blog is crafted for a diverse audience passionate about the future of manufacturing:

• Industry Professionals: Engineers, designers, and manufacturers seeking to stay updated on the latest advancements in additive manufacturing technologies.

• Business Leaders and Entrepreneurs: Those looking to integrate cutting-edge 3D printing solutions into their operations to enhance efficiency and innovation.

• Educators and Students: Academics and learners interested in the evolving landscape of manufacturing for educational and research purposes.

• Technology Enthusiasts: Anyone fascinated by technological innovations and the companies leading the charge in transforming industries.

Whether you’re looking to adopt new technologies, stay informed about industry leaders, or explore the possibilities of additive manufacturing, this blog offers valuable insights to guide your journey.

1. Mosaic Manufacturing

Mosaic Manufacturing stands at the forefront of user-friendly 3D printing solutions. Their flagship printer, the Array, equipped with robotic caretakers, can operate autonomously for days, minimizing the need for constant supervision. This level of automation is unparalleled in the market, especially considering their competitive pricing.

Why They’re Innovative

• Autonomous Printing: Their printers can run independently for extended periods, thanks to advanced filament management systems.

• Exceptional Support: A dedicated team ensures users get the most out of their products, offering comprehensive customer service and troubleshooting.

• Continuous Improvement: Regular firmware updates and software advancements keep them ahead of the curve.

Impact on Manufacturing Workflows

By integrating Mosaic’s Tech, companies can streamline their prototyping and production processes. The ability to print multi-material components in a single print run reduces the need for assembly and accelerates product development cycles. This innovation can lead to significant improvements in efficiency and a reduction in production lead times.

2. Markforged

Markforged is renowned for integrating advanced materials into their 3D printing processes. By combining carbon fiber, metal, and other composites, they’ve enabled the production of parts that rival traditionally manufactured components in strength and durability.

Why They’re Innovative

• Material Diversity: Pioneers in printing with metals and reinforced composites like carbon fiber and Kevlar.

• Cloud-Based Software: Their Eiger software streamlines the printing process with real-time analytics and remote monitoring.

• Industrial Applications: Trusted by aerospace, automotive, and defense sectors for critical components.

Real-World Impact

Companies like Dixon Valve have utilized Markforged’s technology to produce strong, lightweight parts on demand, reducing lead times from weeks to days and cutting costs significantly.

Dixon Valve, a leading manufacturer of hose fittings and accessories, integrated Markforged’s 3D printers into their production process. By adopting Markforged’s composite 3D printing technology, Dixon Valve was able to:

• Reduce Lead Times: Shortened production times from weeks to days for tooling and fixtures.

• Cut Costs: Achieved significant cost savings by printing parts in-house rather than outsourcing or using traditional manufacturing methods.

• Improve Innovation: Enabled rapid prototyping and iteration, allowing their engineering team to innovate more efficiently.

• Produce Strong, Lightweight Parts: Utilized materials like carbon fiber composites to create durable and lightweight components suitable for their demanding applications.

3. AON3D

AON3D specializes in high-temperature 3D printers capable of processing advanced thermoplastics. Their machines enable businesses to produce end-use parts with materials like PEEK and ULTEM™, known for exceptional mechanical properties and thermal resistance.

Why They’re Innovative

• High-Performance Materials: Access to industrial-grade thermoplastics expands application possibilities in demanding environments.

• Open Material Platform: Users aren’t locked into proprietary materials, offering flexibility and cost savings.

• Scalable Solutions: Their printers cater to both small businesses and large-scale industrial operations.

Expert Opinion

“AON3D’s open material platform is a game-changer. It allows for greater experimentation and optimization, which is crucial in R&D environments.”

— Dr. Emily Chen, Materials Scientist at Tech Innovations Lab

4. Stratasys

Stratasys is a veteran in the additive manufacturing industry, continuously innovating since its inception. They offer a wide range of 3D printing technologies, including Fused Deposition Modeling (FDM) and PolyJet, catering to various industries from medical to automotive.

Why They’re Innovative

• Technology Diversity: Multiple printing technologies under one roof, offering solutions for different applications.

• Tailored Solutions: Customizable systems meet specific industry needs, from rapid prototyping to end-use part production.

• Global Impact: A significant contributor to advancing 3D printing standards worldwide.

Notable Achievement

Stratasys partnered with General Motors to produce tooling components, reducing production time from months to weeks and cutting costs by 70%. -

5. Formlabs

Formlabs has democratized access to high-resolution 3D printing with their line of desktop Stereolithography (SLA) printers. Their user-friendly machines deliver professional-quality prints, making advanced manufacturing accessible to designers, engineers, and artists.

Why They’re Innovative

• Accessible Pricing: Professional-grade printers at a fraction of the cost of industrial machines.

• Material Innovation: A broad library of resins, including biocompatible and flexible materials, for diverse applications.

• Ease of Use: Intuitive software (PreForm) and hardware designed for seamless operation.

Educational Impact

Formlabs printers are widely used in universities and design schools, fostering innovation and hands-on learning in engineering and creative disciplines.

6. Carbon

Carbon’s Digital Light Synthesis™ technology has redefined speed and quality in additive manufacturing. By harnessing the power of light and oxygen, they produce parts with exceptional mechanical properties suitable for end-use production.

Why They’re Innovative

• Unprecedented Speed: Up to 100 times faster than traditional 3D printing methods.

• Production-Ready Parts: Outputs are ready for immediate use, minimizing post-processing.

• Industry Partnerships: Collaborations with major brands like Adidas to produce consumer products.

Spotlight: Adidas Futurecraft 4D

Carbon’s technology enabled Adidas to create the Futurecraft 4D sneaker, featuring a 3D-printed midsole tailored to athletic performance, showcasing mass customization in consumer goods.

7. Desktop Metal

Desktop Metal focuses on making metal 3D printing more accessible and efficient. Their systems simplify the traditionally complex process of metal additive manufacturing, opening doors for new applications and industries.

Why They’re Innovative

• Simplified Metal Printing: User-friendly systems that reduce barriers to entry for metal 3D printing.

• Cost-Effective Solutions: Lower operational costs compared to traditional metal manufacturing methods.

• End-to-End Platform: Comprehensive solutions from design to finished part, including software and sintering furnaces.

Industry Application

Automotive companies are leveraging Desktop Metal’s technology to prototype and produce lightweight metal parts, accelerating the development cycle and improving fuel efficiency.

8. EOS

EOS is a pioneer in industrial 3D printing of metals and polymers. Their additive manufacturing solutions are known for precision and reliability, catering to industries with stringent requirements like aerospace and medical devices.

Why They’re Innovative

• Industrial Reliability: Machines built for consistent, high-volume production with minimal downtime.

• Material Excellence: Extensive portfolio of proprietary materials optimized for their systems.

• Global Expertise: Over 30 years of experience and a worldwide presence in additive manufacturing.

Medical Advancements

EOS technology has been instrumental in producing patient-specific medical implants, improving surgical outcomes and patient recovery times.

9. Ultimaker

Ultimaker provides open-source, user-friendly 3D printers known for their reliability and quality. Their commitment to community and collaboration has fostered an ecosystem where innovation thrives.

Why They’re Innovative

• Open-Source Platform: Encourages user innovation and customization, leading to a vibrant community of contributors.

• Educational Impact: Widely used in schools and universities, promoting STEM education and hands-on learning.

• Community Engagement: Strong support network and active user forums enhance the user experience.

Success Story

A small business owner utilized Ultimaker printers to create custom prosthetic limbs, providing affordable solutions to those in need and demonstrating the power of accessible technology.

10. Velo3D

Velo3D is a cutting-edge startup specializing in metal 3D printing solutions that overcome the limitations of traditional manufacturing. Their advanced Sapphire® system and Flow™ print preparation software enable the production of complex geometries without the need for support structures.

Why They’re Innovative

• Support-Free Printing: Ability to print complex metal parts without supports reduces post-processing and material waste.

• High-Quality Metals: Focus on high-performance materials like titanium and Inconel for critical applications.

• Industry Impact: Serving sectors like aerospace and energy with precision parts that were previously impossible to manufacture.

Future Outlook

Velo3D’s technology is paving the way for innovations in space exploration, with companies like SpaceX using their systems to produce rocket engine components.

Conclusion

The additive manufacturing landscape is vibrant and rapidly evolving, thanks to these innovative companies. Their contributions are not only advancing technology but also transforming industries by making manufacturing more accessible, efficient, and customizable.

Future Trends to Watch

• Mass Customization: Personalized products tailored to individual needs will become more prevalent.

• Sustainable Manufacturing: Additive manufacturing reduces waste, supporting eco-friendly initiatives.

• Materials Innovation: Development of new materials will expand the possibilities of 3D printing applications.

• Integration with AI and Automation: Enhanced design processes and autonomous operations will further streamline production.

Fello Agency: Your Tech Industry PartnerFello Agency is a leading tech marketing agency collaborating with some of the world’s most innovative brands. From the depths of quantum computing to the heights of AI, we partner with visionary companies to craft compelling narratives that showcase their groundbreaking technologies. We’re passionate about helping engineers share their stories and make a lasting impact on the world.Contact us today!

By Zachary Ronski.